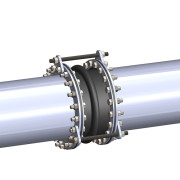

Every scenario is different and every environment is also different. Although these variations may be small, they can have a huge impact on product performance. PES Solutions uses HOLZ expansion joints to ensure each one fits the application.

Original Hand-Crafted, Elastomeric Expansion Joints

These expansion joints can also manage a high range of temperatures and pressures. It can reach temperatures up to 300°F and the Viton® tube/cover will reach up to 400°F. By managing a high range of temperatures and pressures efficiency of the piping systems is increased.

Other Features Include:

- Prevent pipe buckling and fractures.

- An exclusive ring enveloper systems is used to hold steel body rings in place.

- Great for high shock and vibration situations.

- Absorbs motion and displacement between pipe flanges.

This type of expansion joint can be engineered and built to meet any of our customers specific requirements. It is available for all general application, including severe and harsh environments. These expansion joints are specifically ideal for application conditions such as waste water, slurry and sludge. A variety of size options are also available, ranging from 1/2 to 108.

Construction of Piping Expansion Joint

- Tube: The Series 300 piping expansion joint is built with a protective, leak proof lining, which is made of synthetic or natural rubber. The primary function of the tubes is to eliminate the possibility of materials being handled penetrating the carcass.

- Carcass: The expansion joint carcass or body consists of fabric, and when necessary metal.

- Fabric Reinforcement: The carcass fabric reinforcement is the flexibility and supporting member between the tube and the cover.

- Metal Reinforcement: Wire or solid steel rings embedded in the carcass are frequently used for strengthening.

Hand-Built Pressure Piping Expansion Joints with Tire Industry Technology

The hand-built pressure piping expansion joints have superior performance due to its polyester tire cord with modified arch construction. These expansion joints are great for high flow velocity and conditions of high abrasion.

Piping movement challenges are solved with superior movement capabilities without having to use long and expensive multi-arch products. Such qualities as strength, flexibility and safety are increased when compared to the traditional hand-built expansion joints. There’s also precises guidelines for pressure/vacuum capabilities at various temperatures.

Other Features Include:

- Axial extensions, axial compression, lateral deflection, and angular movement

- Available sizes: 10 ID to 96″ ID

- High pressure versions of the 320 (320HP, 320XHP, 320XHPMOD) are available for extreme pressure/full vacuum applications.

- A low pressure version of the 320 (320LP) is available as an economical alternative to the 320 for low pressure/limited vacuum applications.

Ideal for Application Conditions:

- Chemical

- Petroleum

- Sewage

- Sludge

- Slurry

- Waste water

- Other gaseous and abrasive media

The superior performance offered by the Series 320 Expansion Joint is the result of a three year program which thoroughly re-engineered the hand-built expansion joint. This product was created by studying the relationship between the pressure capability of the expansion joint and the media temperature, along with the concurrent movement and spring rates.

Open Arch Construction

- Tube: The Series 320 Expansion Joint has been designed with an extra thick elastromeric tube to yield superior performance in harsh applications. A variety of services conditions such as chemical, petroleum, sewage and other gaseous and abrasive media can be compounded by the tube elastomer.

- Body: The polyester/elastomer reinforcement plies are bonded completely within the tube and cover materials for maximum joint integrity. With the exclusive ring enveloper system the high tensile steel body rings are held in place.

- Cover: The cover elastomer protects the body materials from external conditions. A wide variety of cover elastomers are also available to suit most applications.

Filled Arch Construction

The filled arch joints are recommended for systems where high flow velocity and high abrasion conditions exist. The filled arches are built to eliminate flow turbulence and the collection of suspended solids. These joints are ideal for sewage, sludge, slurry, waste water and process lines.

Lightweight Piping Expansion Joints

The Series 320EZ is a lightweight piping expansion joint introduced specifically for FRP piping. The spring rates are the lowest in the industry with this advanced-design expansion joint. The forces applied to the mating flanges are the lowest in the industry as a result of the innovative design. The 320EZ arch replaces the need for most filled arch, flowing arch and standard arch configurations.

Other Features Include:

- Excellent for compression, extension, lateral, angular deflection and torsional movements

- Recommended for temperatures up to 225°F for Buna-Nitrile and 300°F for EPDM

- Saves money and time by requiring a lighter anchoring system

- Light weight construction for easy handling and freight costs reduction (up to 50% less weight)

- Excellent pressure capacity for low, standard and most high pressure designs

- Reduces stress load with lower reaction force and spring rates

- Available in stock at 1 1/2 ID through 20 ID

320EZ Nitrile Version

Resistant to:

- Hydrocarbons

- Fats

- Oils

- Greases

- Hydraulic Fluids

- Chemicals

320EZ EPDM Version

Resistant to:

- Animal and vegetable oil

- Ozone

- Strong and oxidizing chemicals

Other Types of Piping Expansion Joints

Molded Piping Expansion Joints

Molded piping expansion joints are great excellent performing molded expansion joints with polyester tire cords and modified arch construction. They can reach temperatures up to 300°F and are available in a variety of materials, such as Nitrile, EPDM and Teflon-Lined.

Floating Flange Rubber Expansion Joints

This high-versatile engineered expansion joint is suitable for most high pressure, vacuum, corrosive and vibration situations. They can reach temperatures ranging from 14°F to 275°F. With higher shock and vibration resistance, efficiency is gained.

Vibration Dampeners Expansion Joints

Vibration dampeners expansion joints are ideal for installation on discharge and suction side pumps where turbulence issues or full vacuum service. Temperatures can reach a maximum of 250°F. Non-metallic vibration dampeners in connecting pumps, compressors and other operating equipment allows for the reduced vibration and noise.

Molded PTFE Expansion Joints

These expansion joints are designed to compensate for movement and abate noise in sever corrosive environments. They are available in a wide variety of operating pressures and temperatures in 2, 3, 4 or 5 convolutions. Excessive axial elongation is prevented with built in control rod units with lock nuts.

If you need your expansion joint replaced or repaired PES Solutions has you covered! Contact us today with the link below for more information!

Piping expansion joints are used to accommodate thermal expansion and contraction of piping systems due to changing temperature. An expansion joint is usually a long “L” shaped piece of pipe with an expansion joint fitting on each end. One of the fittings is usually fixed in place while the other end is attached to the piping system.

The primary function of an expansion joint is to absorb the expansion and contraction of piping caused by changes in temperature and pressure.

Hello,

We have a source for rubber expansion joints from Holz. They don’t make metal bellows anymore. We would like to know where you’re located and if we can contact you for quotes for resale of metal bellows.